I have not yet written crafting goals for 2016. November and December were pretty crazy around here! First was my mother-in-law’s 80th birthday on Thanksgiving Day. Then there was the Weavers of Orlando Annual Sale, followed the next weekend by the Holiday Party. Then we had Christmas festivities with my family. On December 28, I flew to Indiana to play matron of honor for Stacy’s wedding on January 2. Chris flew up on December 31 so we got to spend New Year’s Eve together. We just flew home this afternoon, to a cooler and wetter Florida than I left last Monday. Stacy’s reception was held in a building at the same fairgrounds that hosts The Fiber Event. It was so strange to be in that building without seeing rows of lovely fiber, yarn, and tools for sale!

This past week has been busy as the wedding preparations including baking 680 cookies and a 5-tier wedding cake! Stacy, her mother, her aunt, her sister-in-law, and I baked the cookies last Wednesday. Fortunately, we had the use of Stacy’s parents’ church kitchen, which had a commercial oven that could fit 150 cookies at once. We baked all 680 cookies in only 3.5 hours!

After baking cookies, we started on the cakes. I was the lead decorator and giver of orders, as I have been decorating cakes since I was 12! I made the cakes and the lemon curd. Stacy made the chocolate ganache and all the buttercream and mixed lemon buttercream and raspberry buttercream.

Her mother and aunt cut out fondant Christmas trees and painted them with powdered food coloring. I showed Stacy’s sister-in-law how to pipe miniature Christmas trees and she cranked out 250 of them, while Stacy’s mother went behind her putting the little stars on top of each tree.

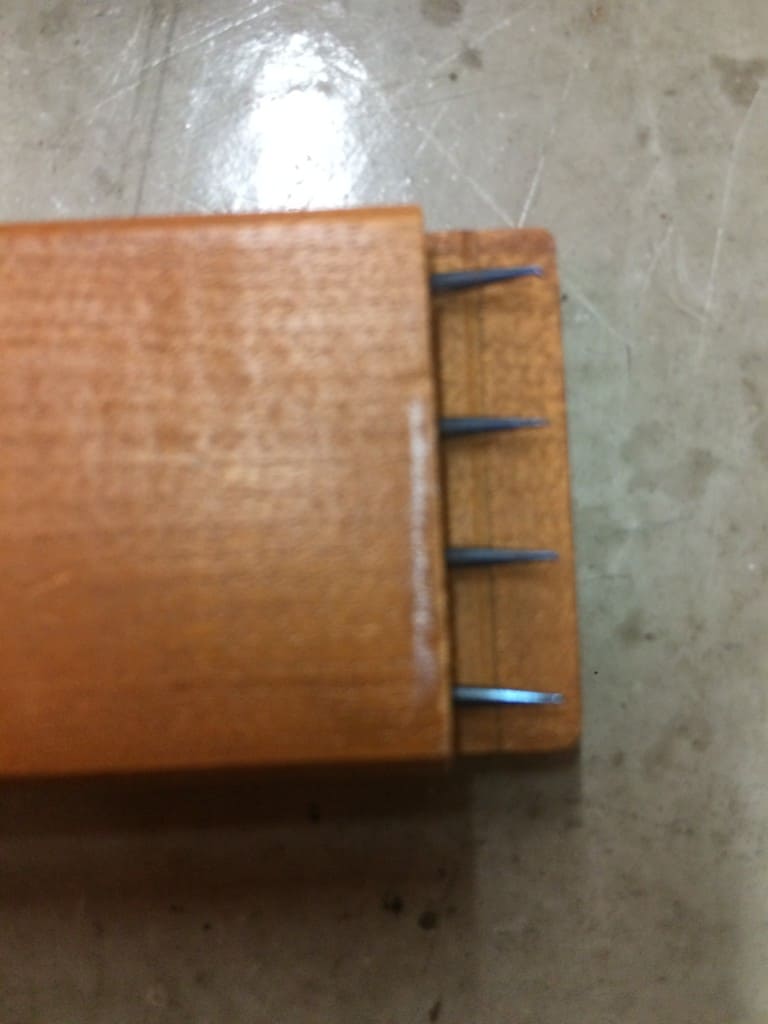

Stacy’s brother cut the dowel rods that help support each tier (using a pipe cutter borrowed from a cousin) and her father cut and sharpened the dowel rod that goes from the top to bottom through all the tiers. When it came time to stack all the cakes, Chris helped me line up my edges correctly. At every step of the way, Stacy and I discussed colors and placement of pieces. This is the first time I’ve made a cake in such a collaborative fashion. It was so much fun, and I love the result!

Now that the wedding is over and I’m home, it’s time to look ahead and lay out my goals for 2016.

Taking Stock

Before I start making ambitious plans for myself, I wanted to look back at 2015, to see what I finished and what remains unfinished. I’m working on a slide show of all the projects I finished this year, and I will publish that later this week. Today, I’m making a list of all my WIPs. It’s a scary list, even though it only includes projects I’ve actually started, not everything in my mental queue!

Knitting WIPs

Projects started in 2015

- TKGA Master Knitter, Level 1

- This week I will start working on addressing my gauge issue

- Splash Socks (started in April 2015)

- Tier Scarf (started in June 2015)

- Miranda Shawl (started in July 2015)

- Bubbles Baby Blanket (started in July 2015)

- Morrigan Shawl (started in August 2015)

- Begonia Swirl Shawl Redux (started in August 2015)

- Finishing

- I still have all the sweaters I got from S. They need to be seamed and blocked. I believe there’s 10 or 11 projects right there!

Projects started prior to 2015

- Dishcloth Advent Calendar

- I need to knit or crochet 18 each of 25 different patterns. This is a list of the knitted dishcloths I’ve finished.

- 18 leaves

- 18 tribble scrubbies

- 18 waffle stitch

- 4 brick pattern

- 16 illusion heart

- 4 random designs (1 each of 4 different patterns)

- Traveling Scarf

- Evenstar

- Baby Blue Monster

Crochet WIPs

- Granny Square Blanket (started in 2014)

- Skulls and Roses Scarves (started in October 2015)

- Dishcloth Advent Calendar

- I need to knit or crochet 18 each of 25 different patterns. This is a list of the crochet dishcloths I’ve finished.

- 18 hyperbolic

- 9 ladderstitch

- 4 or 5 diagonal (corner to corner)

Spinning WIPs

- Camel Down / Silk Blend (started in September 2015)

- Three Feet of Sheep (started in August 2015)

- One pound of BFL (started in November 2015)

Weaving WIPs

Since the only loom I’ve been using is my rigid heddle, I only have one weaving project in process! I started this scarf on December 5, 2015 while at the Weavers of Orlando Annual Sale, so that I could demo weave. I talked to many people throughout the days of the sale and did a fair bit of weaving. I haven’t had time to work on it since.

In addition to this project, I now have the storage unit full of weaving things to sort. This includes minor repairs to one loom (the 36″ Harrisville) and probably a complete refinish of a second loom (the 48″ Macomber). I’m hoping to the the storage unit cleaned out by mid-February, though the refinishing job will most likely take longer than that.

Dyeing

Dyeing doesn’t really have WIPs as something is either dyed or it isn’t. But this is a list of dyeing projects I’ve been meaning to do but haven’t.

- Dye Maple Leaf Shawls (pending since December 2014)

- Dye Triangles (pending since August 2014)

- water source / pH experiment (pending since early 2015)

I’m not sure if this is actually all my WIPs. It’s everything I could find laying about or listed in my Ravelry project pages, but I’m sure I missed more.